Check DRC

The purpose of the DRC inspection is for a general inspection after all PCBs are drawn. After designing a PCB, you need to check the DRC rules on the PCB. The DRC check is carried out according to the rules set by yourself. For example, the minimum spacing set by yourself is 8mil, then in the actual PCB, if the spacing is less than 6mil, an error will be reported.

It is not that boards with errors in the DRC cannot be used. Some rules can be ignored. For example, errors in silk screen printing will not affect electrical properties.

Steps for usage:

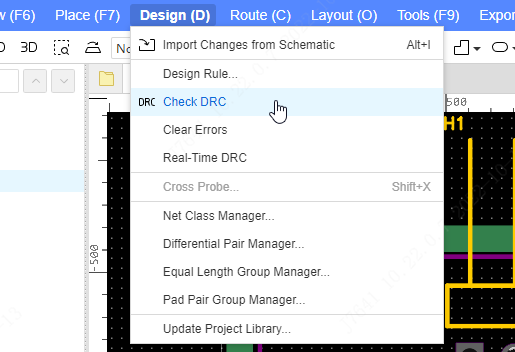

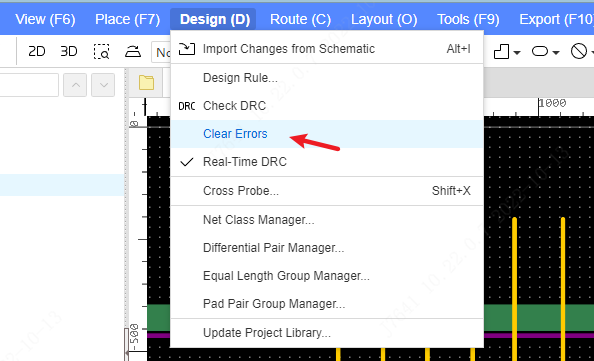

- Top Menu - Design - Check DRC

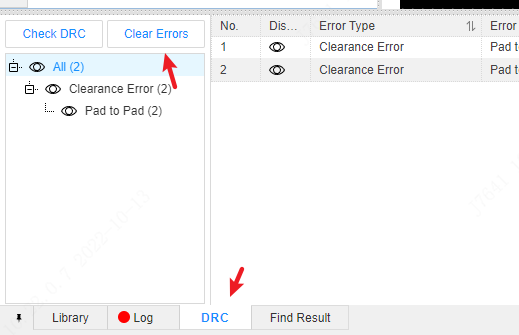

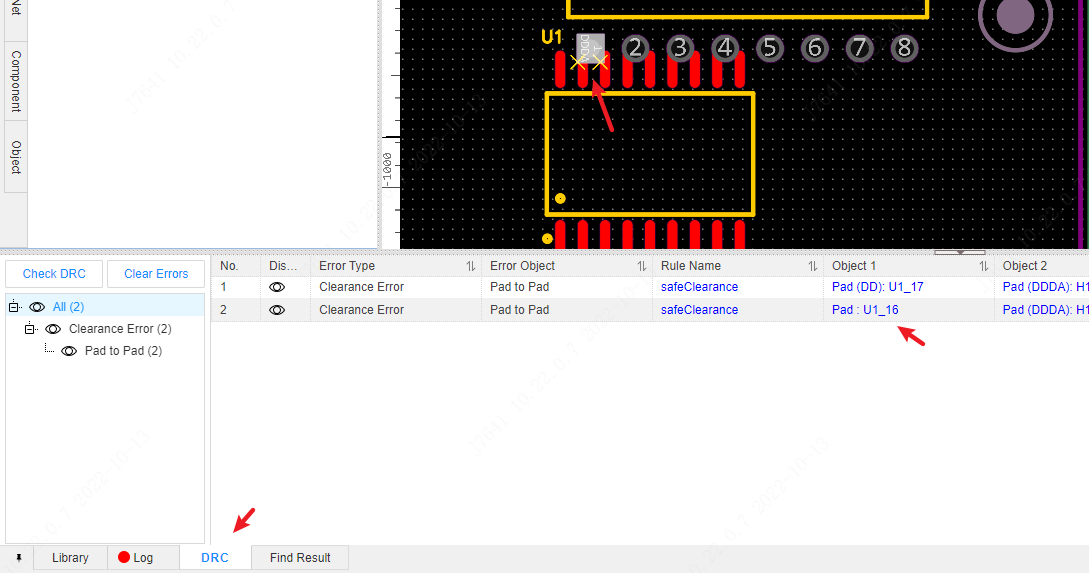

The checked DRC results are displayed on the DRC panel at the bottom, and the corresponding PCB will also have a X symbol. Select and click the wrong point with the mouse to highlight it on the PCB, double-click to zoom in and locate the wrong point.

Real-time DRC

When real-time DRC is turned on, errors can be checked while drawing the PCB.

Steps:

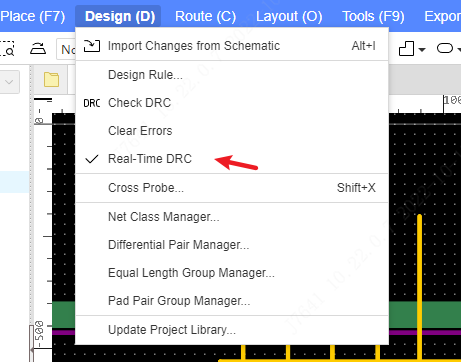

- Top Menu - Design - Real-Time DRC

When drawing the PCB in violation of the rules, the real-time DRC will prompt an error in the PCB.

Reset DRC Error

Reset the DRC check. Via: Top Menu - Design - Clear Errors

or Bottom Panel - DRC - Clear Error resets the checked DRC.